I think a significant reason why some aspects of engineering are so confusing to many is because we get sloppy with the words we use. Changing our habits will make us all less confusing and increase the signal to noise ratio in the industry.

Here are six examples of terms we use all the time, yet they inspire confusion and shaking of heads when casually dropped. The same word means different things to different folks. Let’s take a look at some of the qualifiers we should get in the habit of using. When we hear or see these words, don’t hesitate to ask for clarification.

Let’s look at “bandwidth”, “impedance of an interconnect”, “inductance”, “ground”, “speed”, and “insertion and return loss”.

Bandwidth

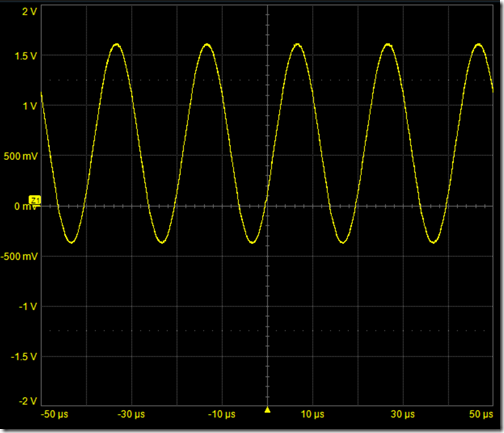

Generally, bandwidth relates to the highest sine-wave frequency component that is significant. The confusion stems from what do we mean by “significant” and that bandwidth can refer to a signal, an interconnect, a measurement, and a model.

Bandwidth of a signal: The highest sine-wave frequency component in the signal, compared to an equivalent ideal square wave; usually the frequency at which the amplitude is below -3 dB of the square wave’s amplitude. Related to the rise time in the signal. To relate the bandwidth of a clock frequency, we are really making an assumption about the rise time of the clock signal.

Bandwidth of an interconnect: The highest sine-wave frequency that can be transmitted down the interconnect with acceptable attenuation. This is so dependent on the spec of what is acceptable. It is less ambiguous to refer to the -3 dB bandwidth of the interconnect, or the -10 dB bandwidth. This is unambiguous.

Bandwidth of a measurement: The highest sine-wave frequency component that is contained in the measurement. Easy to define for a frequency domain measurement, ambiguous for a time domain measurement. We usually define the -3 dB bandwidth of a measurement system as the frequency at which the measured frequency component is reduced to -3 dB of the input signal.

Bandwidth of a model: The highest sine wave frequency where the predictions of the model still match the actual measured response of the structure being modeled. How good the match is is very vague. Usually it is when the plotted simulation response is a few pen widths off from the measured response.

Impedance of an interconnect

Generally, impedance is always the ratio of a voltage to a current. But there are four different types of impedance relating to an interconnect.

Input impedance in the frequency domain: This is the impedance, at each frequency, looking between the signal and return connections at the front of the interconnect. At each frequency, the input impedance is about the total, complete, integrated effects from the entire interconnect including how it is terminated at the end. For an open transmission line, will look capacitive at low frequency and show the resonances of a typical transmission line.

Input impedance in the time domain: This is based on what a TDR might record. The initial input impedance will be the characteristic impedance, or a uniform transmission line, but only for a time less than the round trip time. After this time, there may be reflections which cause the input impedance to vary widely, ending up eventually at the impedance of the far end termination.

Instantaneous impedance of the transmission line: the impedance a signal will see each step along the way as it propagates down the transmission line. Will be constant if the cross section of the line is constant.

Characteristic impedance: Only applied to a uniform transmission line and is the one value of instantaneous impedance a signal will see on the transmission line. The one value of instantaneous impedance “characterizes” the transmission line.

Inductance

Generally, inductance is the number of magnetic field line rings surrounding a conductor per amp of current through the inductor. It is a property of the geometry of the conductors.

Loop-self-inductance: Refers to a conductor in a complete loop, as the total number of rings of magnetic field lines around the conductor per amp of current in that loop.

Loop-mutual-inductance: Refers to two conductors each as complete loops, as the total number of rings of magnetic field lines around one conductor produced by the current in the other conductor, per amp of current.

Partial-self inductance: The number of rings of magnetic field lines around a part of a loop, per amp of current in that loop. Cannot be directly measured, but can be calculated mathematically.

Partial-mutual inductance: The number of rings of magnetic field lines around a part of a loop, per amp of current through another part of the loop. Cannot be directly measured, but can be calculated mathematically.

Total inductance: the total number of rings of magnetic field lines around a part of a loop from all the currents contributing magnetic field lines, usually the partial self-inductance of the section, minus the partial mutual to all other parts of the loop. Can be measured from the voltage generated from a dI/dt through the section of conductor.

Ground

Generally a specific conductor identified in a system based on how it is used.

Circuit ground. Generally, the circuit nodes or terminals which are the lowest voltage point in a unipolar supplied circuit, or the mid voltage point in a bipolar power supplied circuit. It is from this conductor that the voltage on other nodes is measured relative to. Other than being the reference conductor, there is nothing special about the circuit ground.

Digital ground. Usually the circuit ground conductor which is the return path for the digital signals. The return path can also be a conductor with a DC voltage on it.

Analog ground. Usually the circuit ground conductor which is the return path for analog signals. Other than extreme cases where fractions of a mV DC drop are important, analog and digital ground can be the same conductor if a continuous plane is used. The return currents will remain separate in the plane, following the location of the signal line. The idea of separating analog and digital ground applies when the return path is not a plane, like leads in a connector or pins in a package. In these cases, ground bounce from digital signals can create huge cross talk on the analog signals.

Chassis ground. This is the metal housing associated with the product. It often provides shielding to reduce EMI. It also acts as a safety shield to product any user who might touch the chassis. Cable shields should be connected to the chassis ground in order to reduce common currents on the shield. In this case, the cable shield becomes an extenuation of the chassis. Usually the circuit ground of the board is connected to the chassis ground at one point. If multiple points are used, there may be some low frequency return currents flowing in the chassis. Of course, if the enclosure is plastic, there is no chassis ground.

Earth ground. This is the connection that ultimately leads to a copper rod driven into the ground (literally) to provide a reference voltage throughout a house or building. This is a safety issue required by some building codes. The round hole in an AC outlet is connected to this copper rod. UL requires that chassis ground be connected to earth ground as a safety feature. Ground fault interrupter (GFI) sockets are designed to disconnect power to a device if more than a few micro amps of current from the low side of the power mains flows through the earth ground connection. Of course, a car, satellite or other portable device has no connection to earth ground.

Speed

The speed of a signal is the most confusing term as it is used in two completely different contexts. Speed is generally related to the velocity of the signal. But it is also used to refer to the rate of data transfer.

Speed of light in air: about 1 foot per nsec, 12 inches/nsec, or 30 cm/nsec

Speed of light in most laminates. Since the Dk of most laminates is about 4, the speed of a signal in the laminate is about 6 inches/nsec or 15 cm/nsec

Speed of electrons in a conductor. Even in the extreme of cases, the speed of an electron in a copper wire is about 1 cm/sec, the speed of an ant. It has nothing to do with the speed at which an electric and magnetic field will propagate in a transmission line.

The clock frequency of a system: The frequency, usually in MHz, of the repetitive reference signal to synchronize system operations. The clock frequency of many high end microprocessors has increased over the last 30 years from 16 MHz. to 2.5 GHz.

The Nyquist frequency of a serial link signal: This is the frequency of the underlying clock of a serial link signal. It is the clock frequency when the data transition rate is the highest, 10101010101. This looks like a square wave and its frequency is the Nyquist. Since there are two bits per clock cycle, Double Data Rate (DDR), the Nyquist frequency is half the data rate. A 10 Gbps NRZ (non-return to zero) data pattern has a Nyquist of 5 GHz. The Nyquist and the encoding scheme, determine the maximum rate of data transmission in the channel, or the channel capacity.

The data rate of a serial link: The rate at which the data is transmitted as bits per second. In an NRZ pattern, with just two voltage levels for the signal, referred to as PAM2, each clock cycle has 2 bits of information encoded on it. The channel capacity for the data rate is twice the Nyquist frequency. If the Nyquist is 5 GHz, the data rate is 10 Gbps.

The baud rate. We often refer to the data content in a signal as the data payload. When an encoding scheme uses extra bits to carry routing information or synchronization information, not all the bits are payload data. We use the term baud rate to refer to the rate at which symbol transitions are transmitted. A symbol is the smallest unit of modulation. The data rate of Ethernet may be 10 Gbps but with a small percentage of the possible symbols being non-payload data, the actual transmission rate of symbols, the baud rate, is 10.3125 Gbps.

Insertion and return loss

These are throwback terms from the old days of how microwave measurements used to be performed. Two halves of a well matched fixture were measured separated and when connected together. When the device is inserted, the reflected signal and transmitted signal is measured.

The return loss is the loss in the returned signal of the open when the DUT is inserted. When open, all the signal returns. When the DUT is inserted, the better the match in the fixture, the less energy is returned; there is a large return loss, compared to an open. The larger the loss in the returned signal, compared to when the fixtures were open, the better the match.

The insertion loss is the ratio of the power received when the fixture is connected, compared with when the DUT is inserted. The less energy coming through the DUT, the more the insertion loss.

In both cases, the loss is defined as a positive dB value. The larger the value, the more loss. A large insertion loss means we lost a lot of signal when we inserted the DUT- not much gets through, not much is reflecting.

When we measure the S11 or S21 values of an interconnect, the magnitudes, in dB, are always negative for passive elements. Yet, we get in the habit of calling them return and insertion loss. To avoid the sign confusion, the industry is migrating to accepting return and insertion loss as either positive or negative.

The following terms apply to a uniform 2-port interconnect.

S11: the S-parameter = the reflection coefficient. The magnitude of S11, in dB, is the return loss, either as a positive or negative dB value. Referring to S11 as the reflection coefficient is unambiguous.

S21: the S-parameter = the transmission coefficient. The magnitude of S21, in dB, is the insertion loss, either as a positive or negative dB value. Referring to S21 as the transmission coefficient is unambiguous.

Attenuation = the attenuation in an interconnect, usually expressed in dB. It is usually a positive value. Larger values of attenuation in dB means more signal loss. Attenuation = -S21 in dB for a matched interconnect

Attenuation per length = dB/in or dB/m as a positive value.

These are just a few examples I encounter all the time. If we are not careful when we use these terms we leave confusion in our wake. Get in the habit of adding the qualifiers and it will help us communicate and think more clearly. Ultimately, we reduce the entropy in the universe and increase the signal to noise ratio in the industry.